Product Description

3D printed basketball flooring, as a new type of flooring material that combines advanced technology and personalized design, is gradually demonstrating its unique charm in the field of sports facilities. The following is a further exploration of 3D printed basketball flooring, including its technical principles, specific advantages, potential challenges, and future prospects.

Technical principles

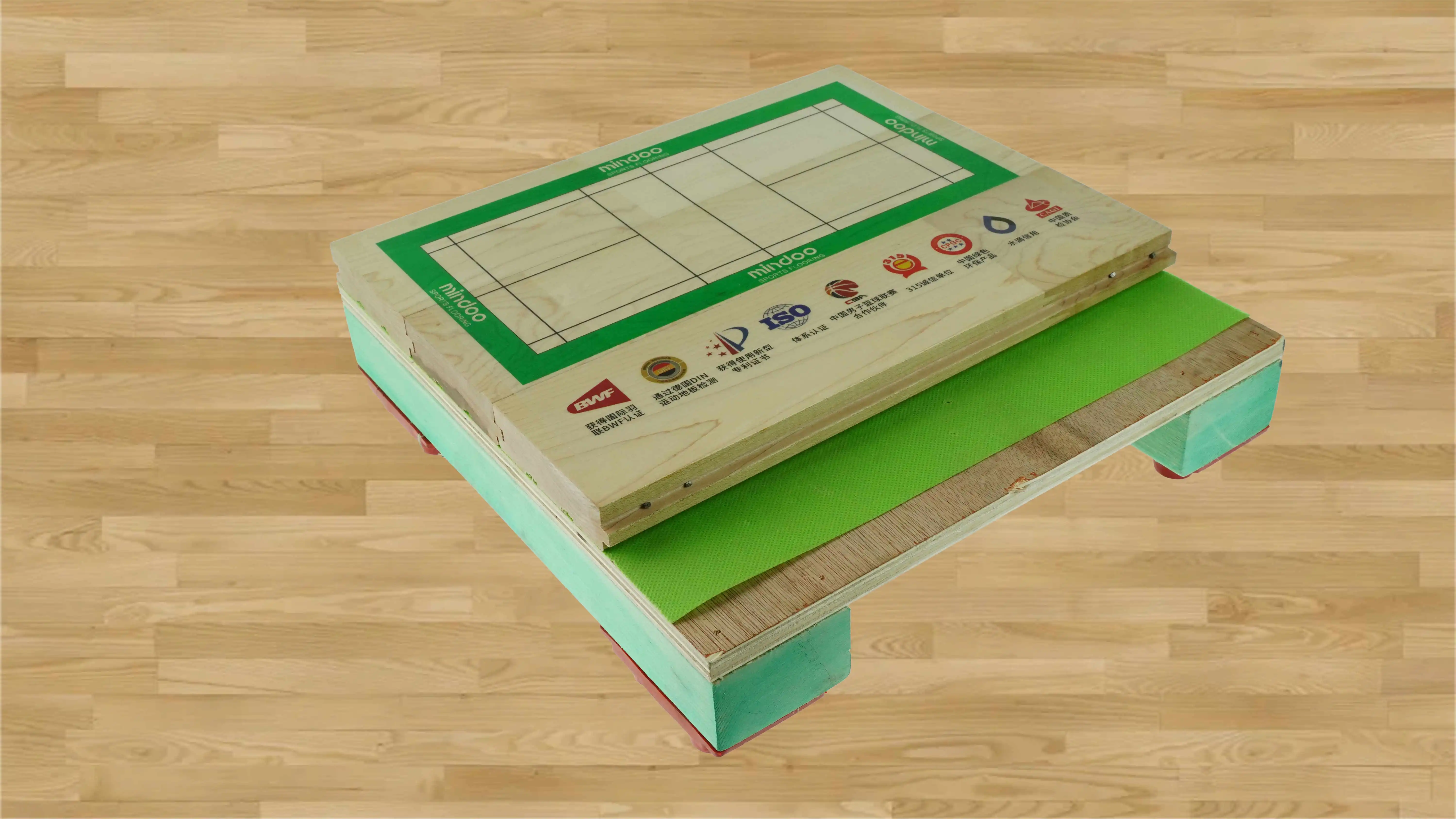

The technical principle of 3D printing basketball flooring is based on additive manufacturing technology, which constructs three-dimensional objects by stacking materials layer by layer. During the printing process, computer-controlled nozzles or laser beams will precisely spray or solidify layer after layer of material onto the floor material according to a preset design pattern. These materials can be plastic, resin, rubber, or special composite materials that have undergone special treatment to ensure wear resistance and durability.

Specific advantages

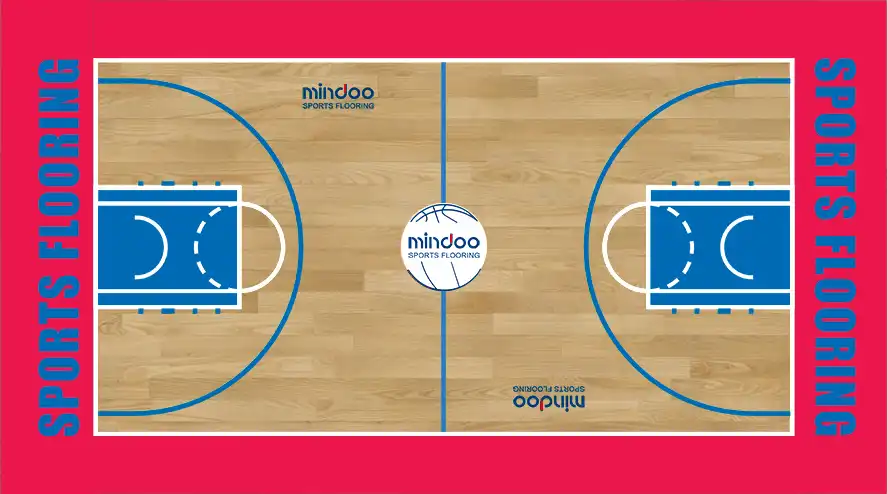

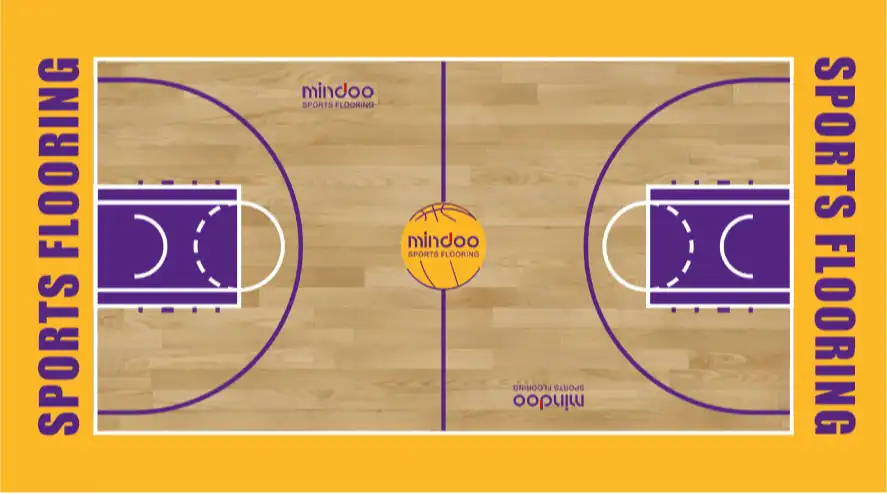

· Highly personalized: 3D printing technology allows designers and customers to achieve almost any pattern, texture, and color combination on the floor, thereby meeting specific aesthetic and functional needs.

· Excellent performance: High quality printing materials and processes ensure the wear resistance, slip resistance, and impact resistance of the floor, providing athletes with an excellent sports experience and safety guarantee.

· Easy to maintain: Due to the special properties of printing materials, 3D printed basketball flooring typically has lower maintenance costs and is easier to clean and maintain.

· Environmentally friendly and sustainable: Flooring printed with eco-friendly materials helps reduce its impact on the environment, in line with the modern concept of sustainable development.

Potential challenges

· Cost issue: Despite the continuous cost reduction of 3D printing technology, its initial investment is still relatively high compared to traditional flooring materials, which may limit its popularity in certain markets.

· Technological maturity: Although 3D printing technology has made significant progress, there are still limitations in printing speed, material selection, printing size, and other aspects that require continuous technological innovation to overcome.

· Market acceptance: As an emerging technology, the market acceptance of 3D printed basketball flooring still needs time to develop, especially in the context of the relatively mature traditional basketball court flooring market.

Future prospects

· Technological innovation and cost reduction: With the continuous advancement of 3D printing technology and the expansion of market size, it is expected that printing speed will increase and material costs will decrease, thereby promoting the widespread application of 3D printed basketball flooring.

· Diversified application scenarios: In addition to basketball courts, 3D printing flooring technology is expected to expand to other sports fields and public places, such as football fields, tennis courts, gyms, etc., providing personalized flooring solutions for these venues.

· Intelligence and Interconnection: In the future, 3D printed basketball flooring may be combined with intelligent sensors, the Internet of Things, and other technologies to achieve real-time monitoring and data analysis of the venue status, providing more accurate services and management for athletes and venue managers.

In summary, 3D printed basketball flooring, as an innovative flooring solution, is gradually demonstrating its unique charm and broad prospects. With the continuous advancement of technology and the expansion of the market, it is expected to play an increasingly important role in the construction and renovation of sports facilities in the future.

Send Inquiry

You may like